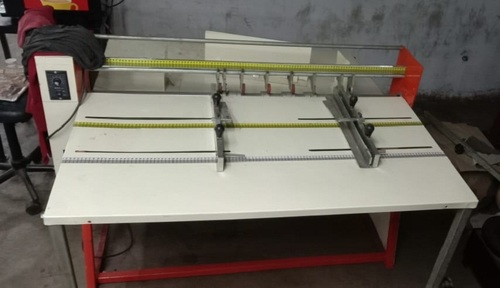

Paper Bag Creasing Machine

MOQ : 1 Piece

Paper Bag Creasing Machine Specification

- Operating Temperature

- 5C to 45C

- Accuracy

- 0.5 mm

- Power Rating

- 1.5 kW

- Frequency

- 50 Hz

- Production Capacity

- 5000-6000 pcs/hr

- Cooling System

- Air cooled

- Lubricating System

- Manual lubrication

- Model No

- PB-CR6000

- Voltage

- 220 V

- Noise Level

- <75 dB

- Frame Type

- Heavy Duty Steel Frame

- Motor Power

- 1.5 HP

- Machine Type

- Creasing / Scoring Machine

- Features

- Sturdy frame, adjustable creasing wheel, compact design

- Control System

- Manual and limit-switch controlled

- Drive

- Belt Drive

- Product Type

- Paper Bag Creasing Machine

- Technology

- Mechanical creasing technology

- Power Source

- Electric

- Operating Type

- Semi-Automatic

- Power

- 1.5 kW

- Pressure

- Adjustable up to 1.2 tons

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 1800 x 1200 x 1400 mm

- Weight (kg)

- 750 kg

- Color

- Blue & White

- Usage & Applications

- Creasing and forming lines on paper bag blanks

- Suitable Bag Types

- Flat and gusseted paper bags

- Feed Type

- Manual top feed

- Transportation Type

- Floor mounted, caster wheels optional

- Machine Finish

- Anti-corrosive enamel

- WorkingSpeed

- 60 cycles/min

- Ambient Humidity

- 80% non-condensing

- Operator Requirement

- 1 operator

- Safety Mechanism

- Emergency stop switch

- Creasing Width Range

- 5-15 mm

- Spare Parts Availability

- Yes

- Maximum Paper Width

- 1000 mm

- Installation Support

- Available

- Minimum Paper Thickness

- 70 GSM

Paper Bag Creasing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cheque, Cash in Advance (CID), Cash Advance (CA)

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Paper Bag Creasing Machine

Paper bag creasing machine is used for creasing bag top and bottom to make square bottom paper bag by hand. Machine is made up of isi angles and cast iron body with vibration free performance.Superior Creasing Accuracy

The PB-CR6000 creasing machine guarantees line accuracy of 0.5 mm, essential for maintaining consistent quality in paper bag production. Experience adjustable pressure up to 1.2 tons, allowing adaptable performance for various applications, while its air-cooled system maintains optimal temperature during high-speed operations.

Efficient and Flexible Operation

With a working speed of 60 cycles per minute and a power rating of 1.5 kW, this machine streamlines creasing for both small- and large-scale requirements. One operator can efficiently control the semi-automatic process, thanks to user-friendly manual and limit-switch controls, further supported by floor mounting and optional caster wheels.

Designed for Durability and Safety

Finished in anti-corrosive enamel and equipped with a sturdy heavy-duty steel frame, the PB-CR6000 withstands demanding usage. Key safety elements include an emergency stop switch and manual lubrication system, ensuring both operational safety and prolonged machine life. Installation support and steady spare parts availability enhance reliability.

FAQ's of Paper Bag Creasing Machine:

Q: How does the manual top feed system work in the PB-CR6000 Paper Bag Creasing Machine?

A: The manual top feed system requires the operator to place paper bag blanks onto the input tray, aligning them carefully for precise feeding. This approach streamlines the setup process, allowing the operator to monitor and ensure each blank is correctly positioned before creasing begins.Q: What are the steps involved in the installation of this creasing machine?

A: Installation support is provided by the manufacturer or supplier. The process generally involves positioning the floor-mounted machine (with optional caster wheels if needed), connecting it to an electric power source (220 V, 50 Hz), verifying operational safety features such as the emergency stop switch, and calibrating the creasing wheels for intended bag sizes.Q: When is maintenance required for the PB-CR6000, and what does it entail?

A: Regular maintenance is recommended based on usage frequency. The machine has a manual lubrication system that should be checked and applied as needed to preserve mechanical integrity. Ensuring the creasing wheels and belt drive remain in optimal condition will also help sustain the machine's performance.Q: Where is this creasing machine suitable for use?

A: The PB-CR6000 is ideal for paper bag manufacturing units, supply chains, or trading operations in India requiring high-speed, accurate creasing on flat and gusseted bags. It operates reliably within ambient humidity up to 80% non-condensing and a temperature range of 5C to 45C.Q: What types of paper bags can be processed with this machine?

A: This machine is engineered for creasing a variety of paper bag types, specifically flat and gusseted configurations. It accommodates paper thicknesses starting at 70 GSM and widths up to 1000 mm, making it versatile for different bag design requirements.Q: How does the emergency stop switch enhance operator safety during machine operation?

A: The emergency stop switch allows the operator to instantly halt machine operation in case of irregularities or hazards, reducing the risk of injury and preventing damage to the paper bag blanks or machine components.Q: What are the benefits of the adjustable creasing wheel and sturdy frame design?

A: The adjustable creasing wheel enables customization of creasing widths between 5 to 15 mm, supporting diverse production needs. The heavy-duty steel frame ensures stability and durability, contributing to the machine's reliability and consistent creasing quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free