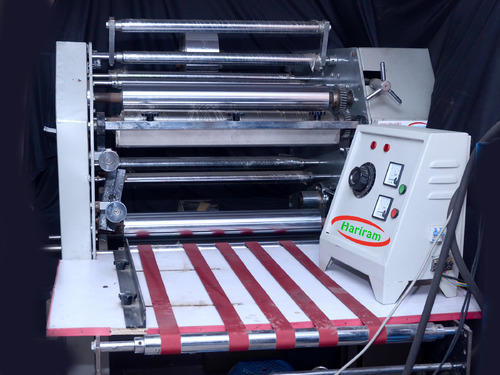

Paper Roll Lamination Machine

Paper Roll Lamination Machine Specification

- Max Film Width

- 800 mm

- Max Lamination Temp

- 140C

- Membrance Core Size

- 72 mm

- Lamination Speed

- 25 meters/min

- Product Type

- Paper Roll Lamination Machine

- Material

- Mild Steel Body

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Digital Panel

- Drive Type

- Electric Motor Driven

- Heating System

- Infrared Heating

- Power Source

- Electric

- Voltage

- 220-240 V AC

- Weight (kg)

- 580 kg

- Dimension (L*W*H)

- 2150 x 900 x 1450 mm

- Capacity

- 1200 - 1500 rolls per shift

- Feature

- High Efficiency, Low Maintenance

- Color

- Industrial Grey & Blue

- Type of Rollers

- Chrome Plated Steel Rollers

- Speed

- 25 m/min

- Input Paper Size

- Up to 32 inches

- Suitable Paper

- Craft, Duplex, Art Paper

- Roller Pressure Adjustment

- Pneumatic

- Operator Requirement

- Single Operator

- Laminating Thickness

- 0.05 mm 0.25 mm

- Energy Consumption

- 4 kW per hour

- Application

- Book Covers, Posters, Packaging Material

- Film Type

- BOPP, PET, Polyester

- Noise Level

- 75 dB

- Preheating Time

- 15 minutes

- Safety Features

- Emergency Stop, Overheat Protection

Paper Roll Lamination Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA)

- Main Domestic Market

- All India

About Paper Roll Lamination Machine

Being a leading manufacturer and supplier of Paper Roll Lamination Machine, we are instrumental in the process of manufacturing. We are backed by a team of expert professionals who make sure that this machine is made in full compliance with international quality standards. It is highly demanded among our clients for its numerous benefits and features such as compact design, high strength & durability, and long lasting service life. This machine is duly checked for its functionality and proper working by a team of quality analysts prior to dispatch to ensure that our clients get a flawless range of products from us. Paper Roll Lamination Machine offered by us is made available in different models to cater to different clients who have different budget and requirements.

Technical Specification

|

| HR-113-A(24) | HR-113-B(30) | HR-113-C(24) |

| Width (MM) | 1260 | 1360 | 1610 |

| Height (MM) | 2120 | 2120 | 2120 |

| Length (MM) | 1520 | 1520 | 1520 |

| Max. Flim Roll Width (MM) | 560 | 710 | 965 |

| Max. Flim Roll Dia | 400 | 400 | 400 |

| Paper Weight | 45 To 500 Gsm | 45 TO 500 GSM | 45 TO 500 GSM |

| Production Rate | 20 Mtrs / Min | 20 MTRS / MIN | 20 MTRS / MIN |

| Power Source (230 V Ac Single Ph) | 2 Hp | 2 HP | 3HP |

| Roll To Attachment | Inbuilt | Inbuilt | Inbuilt |

| Sheet To Roll Attachment | Inbuilt | Inbuilt | Inbuilt |

Efficient Lamination for Diverse Applications

This machine is expertly crafted for laminating a range of paper types such as craft, duplex, and art paper. Its compatibility with multiple film typesBOPP, PET, and Polyesterexpands its application versatility across book covers, posters, and packaging. The robust design combines mild steel construction with chrome-plated steel rollers to ensure consistent, professional-quality results every time.

User-Friendly Semi-Automatic Operation

Operated simply by a single person, the machine features a digital panel for straightforward control and adjustment. Pneumatic roller pressure supports uniform lamination, while critical safety elements, including an emergency stop and overheat protection, enhance operator security. Maintenance is minimized, reducing downtime and allowing for continuous production during each shift.

Performance and Safety You Can Trust

With a lamination speed of 25 m/min and a capacity of 1200 to 1500 rolls per shift, the machine ensures high output. Infrared heating and precise digital adjustments guarantee evenly laminated finishes. A comparatively low operating noise level and energy-efficient design further support comfortable and cost-effective usage for businesses seeking productivity and reliability.

FAQs of Paper Roll Lamination Machine:

Q: How does the paper roll lamination process work with this machine?

A: The machine first preheats for approximately 15 minutes using its infrared heating system. The selected film (BOPP, PET, or Polyester) and paper (up to 32 inches wide) are loaded onto their respective rollers. The digital panel allows users to set the required temperature (up to 140C) and lamination speed (25 m/min). Pneumatic pressure ensures consistent adhesion as the chrome-plated steel rollers bond the film to the paper, delivering evenly-laminated rolls.Q: What types of films and papers are compatible with this lamination machine?

A: This machine works with BOPP, PET, and Polyester films, handling film widths up to 800 mm. It supports lamination of various papers, including craft, duplex, and art paper, making it ideal for book covers, posters, and packaging material.Q: When is it necessary to adjust the roller pressure, and how is it done?

A: Adjusting roller pressure is crucial when changing paper thickness or when different lamination finishes are required. This adjustment is made pneumatically via the machines control system, ensuring uniform application for laminating thicknesses between 0.05 mm and 0.25 mm.Q: Where can this lamination machine be installed and operated?

A: Designed for industrial use, the machine is suitable for print shops, packaging facilities, and book manufacturing units. Its compact design and standard voltage requirements (220240V AC) facilitate installation in production environments across India.Q: What safety features are built into the lamination machine?

A: Safety measures include an emergency stop button and overheat protection. These features promptly halt the operation in critical situations to safeguard both the operator and the machine, making it reliable and safe.Q: How many operators are required, and what is the average operational capacity?

A: Only a single operator is needed due to the machines user-friendly digital panel and semi-automatic operation. It can handle between 1200 to 1500 rolls per shift, depending on the size and type of materials used.Q: What are the key benefits of using this machine for lamination tasks?

A: Key benefits include high efficiency with low maintenance needs, quick setup due to a 15-minute preheating period, superior lamination quality via precise pneumatic pressure and digital controls, and robust safety systems. Its versatility and high-speed output make it an excellent investment for businesses aiming to scale up their laminating operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paper Plate Lamination Machine Category

Paper Plate Lamination Machine

Price 260000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 20003000 plates per hour

Automatic Grade : Other, SemiAutomatic

Product Type : Other, Paper Plate Lamination Machine

Lamination Machine

Price Range 260000.00 - 350000.00 INR

Minimum Order Quantity : 1 Unit

Capacity : 8001000 Kg/day

Automatic Grade : Automatic

Product Type : Cold/Hot Laminating Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS