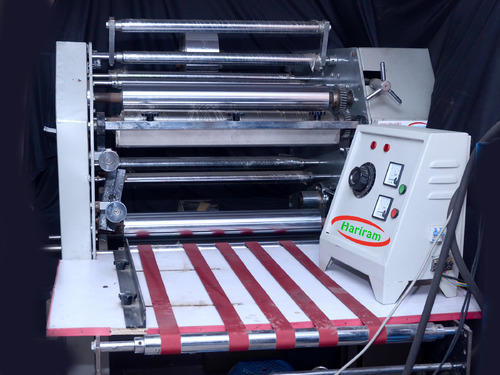

Paper Plate Lamination Machine

Price 260000.00 INR/ Unit

Paper Plate Lamination Machine Specification

- Lamination Speed

- 10 m/min

- Max Film Width

- 600 mm

- Max Lamination Temp

- 130C

- Membrance Core Size

- 75 mm

- Product Type

- Paper Plate Lamination Machine

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- PLC Control

- Drive Type

- Electric Motor

- Heating System

- Roller Heating System

- Power Source

- Electricity

- Voltage

- 220240 V

- Weight (kg)

- 350 kg

- Dimension (L*W*H)

- 1750 mm x 820 mm x 1250 mm

- Capacity

- 20003000 plates per hour

- Feature

- Rust Proof, Easy Operation, Energy Efficient

- Color

- Blue & Silver

- Type of Rollers

- Chromed Steel Rollers

- Speed

- 815 m/min

- Input Paper Size

- Up to 24 inches

- Suitable Paper

- Duplex Board, Craft Paper, Silver Paper

- Maintenance

- Low Maintenance

- Minimum Paper Thickness

- 80 GSM

- Maximum Paper Thickness

- 350 GSM

- Cooling System

- Air Cooling

- Installation Service

- Provided

- Glue Applicator Type

- Roll Coating

- Finish Type

- Matte / Glossy

- Noise Level

- Low

- Pre Heating Unit

- Available

- Application

- Disposable Plate Lamination, Sheet Lamination

- Operator Required

- 1 Person

- Safety Features

- Overload Protection, Emergency Stop Switch

- After Sales Service

- Available

- Film Type Supported

- Poly, BOPP, Polyester

Paper Plate Lamination Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash on Delivery (COD), Cheque, Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Western Union, Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Delivery Point (DP), Days after Acceptance (DA), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Main Export Market(s)

- Australia, South America, Eastern Europe, Middle East, Africa, Central America, Western Europe, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO certified

About Paper Plate Lamination Machine

Operating from Surat, Gujarat, we are a reputed manufacturer and supplier of excellent quality Paper Plate Lamination Machine. It is made with utmost precision and fabricated using top notch quality raw materials under proper guidance and supervision of deft professionals. This machine is extensively used for laminating paper plates with plastic film to make them water proof and more durable. It has very high efficiency and works with plates with different sizes and designs. All parts of this machine are easily replaceable so it is very easy to maintain. Moreover, due to large number of choices available for purchasing Paper Plate Lamination Machine, clients can fulfill their requirements.

Lamination Machine:

- 24" 160000-

- 30" 180000/-

- 40" 210000/-

Technical Specification:

|

| HR-113-A(24) | HR-113-B(30) | HR-113-C(24) |

| Width (MM) | 1260 | 1360 | 1610 |

| Height (MM) | 2120 | 2120 | 2120 |

| Length (MM) | 1520 | 1520 | 1520 |

| Max. Flim Roll Width (MM) | 560 | 710 | 965 |

| Max. Flim Roll Dia | 400 | 400 | 400 |

| Paper Weight | 45 To 500 Gsm | 45 TO 500 GSM | 45 TO 500 GSM |

| Production Rate | 20 Mtrs / Min | 20 MTRS / MIN | 20 MTRS / MIN |

| Power Source (230 V Ac Single Ph) | 2 Hp | 2 HP | 3HP |

| Roll To Attachment | Inbuilt | Inbuilt | Inbuilt |

| Sheet To Roll Attachment | Inbuilt | Inbuilt | Inbuilt |

Efficient Lamination with Superior Finish

The machine delivers both matte and glossy finishing options for disposable plates, ensuring a professional appearance. Its high-speed operation and wide input paper compatibility allow users to meet large volume demands efficiently while maintaining consistent quality on materials such as duplex board, craft paper, and silver paper.

Simplified and Safe Operation

Requiring just one operator, the lamination process is streamlined by PLC controls, emergency stop switches, and overload protection. The user-friendly interface and low-maintenance design make it ideal for manufacturers seeking hassle-free production, supported by installation and after-sales services for peace of mind.

Energy Efficiency and Robust Construction

Built from mild steel with a rust-proof finish, this machine is engineered to last. Its energy-efficient electric motor and roller heating system minimize operating costs, while the air cooling system preserves film quality and machine durability, ensuring reliable lamination over time.

FAQs of Paper Plate Lamination Machine:

Q: How does the glue applicator type (roll coating) improve the lamination process on this machine?

A: The roll coating glue applicator ensures uniform adhesive distribution across each sheet, resulting in consistent bonding and reducing wastage. This precise application enhances lamination quality and provides strong adhesion for disposable paper plates.Q: What types of film can be used with this lamination machine?

A: The machine supports lamination using Poly, BOPP, and Polyester films, allowing flexibility for different finishing requirements. Users can select the film type based on desired properties and end-use applications.Q: When is it suitable to use this machine for plate or sheet lamination?

A: This machine is ideal for businesses that regularly need to laminate disposable plates or sheets in bulk, especially when working with paper thicknesses between 80 GSM and 350 GSM. Its fast output makes it suitable for high demand situations.Q: Where can installation and after-sales services be accessed for this machine?

A: Comprehensive installation and after-sales services are provided by the manufacturer, supplier, or trader across India. Customers receive professional on-site assistance and ongoing support for maintenance needs.Q: What is the typical process for laminating disposable plates using this machine?

A: The process begins with feeding the suitable paper into the machine, applying adhesive via the chromed steel rollers, heating through the roller heating system, and then cooling with air circulation. The lamination finishes as either matte or glossy, depending on settings, with completed plates collected at the output end.Q: How does the machine benefit operators in terms of usage and maintenance?

A: Designed for single-person operation, the machine offers intuitive PLC controls and essential safety features such as overload protection and emergency stop. Its low-maintenance structure allows users to maximize uptime with minimal servicing.Q: What are the key advantages of using this lamination machine for business?

A: The machine offers reliable performance with speeds up to 15 m/min and a capacity of 20003000 plates per hour. Its energy efficiency, robust construction, and flexibility for various paper and film types make it a valuable asset for scaling production and ensuring product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paper Plate Lamination Machine Category

Paper Roll Lamination Machine

Price Range 265000.00 - 350000.00 INR

Minimum Order Quantity : 1 Piece

Product Type : Other, Paper Roll Lamination Machine

Automatic Grade : Other, SemiAutomatic

Dimension (L*W*H) : 2150 x 900 x 1450 mm

Capacity : 1200 1500 rolls per shift

Lamination Machine

Price Range 260000.00 - 350000.00 INR

Minimum Order Quantity : 1 Unit

Product Type : Cold/Hot Laminating Machine

Automatic Grade : Automatic

Dimension (L*W*H) : 10*8*6 Foot (ft)

Capacity : 8001000 Kg/day

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free